GRIPPERS FOR PALLETISING

At IMASD Robotics Engineering, we create our own grippers, adapting them to the solutions we develop and produce.

THEY GUARANTEE HIGH-PACE PALLETISING

Our palletisers have a wide range of grippers, created exclusively for our engineering equipment, which areinterchangeable with one another, vastly increasing the modularity of our solutions.

Its light weight ensures a consistent high pace, while greatly increasing the possibilities of palletising different types of boxes and products.

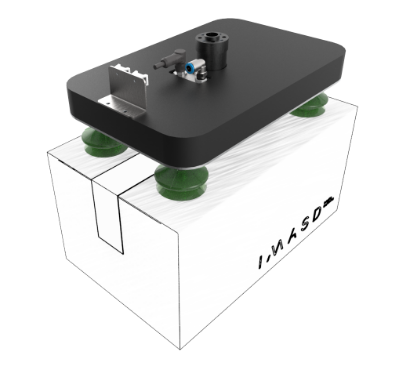

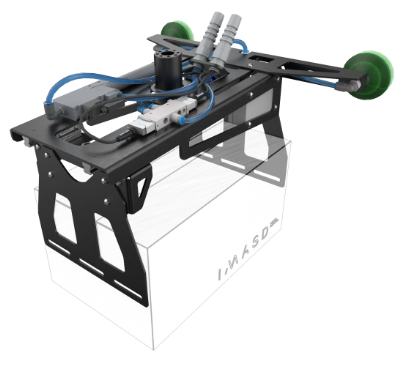

VACUUM GRIPPERS

Zoned multi-suction gripper.

Designed and developed to work with B1 closed boxes of different dimensions at a fast pace.

RELIABILITY AND SECURITY

Each box is picked up securely thanks to the distribution of suction cups. It also verifies presence with each pick-up for reliability and security during the complete palletising process.

ENERGY-EFFICIENCY

As a zoned gripper, the expenditure of air is restricted to the suction cups that are activated, supporting energy efficiency.

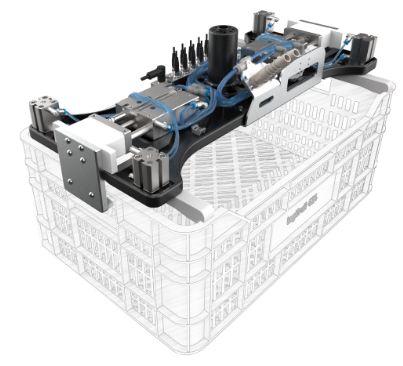

MECHANICAL GRIPPER

For rigid and open boxes.

Our mechanical gripper is specifically designed to handle rigid plastic boxes and open trays of varying sizes.

RELIABILITY AND SECURITY

Thanks to our top-quality suction system, it picks up and palletises with total ease.

BOX PRESENCE VERIFICATION

The integrated box presence verification guarantees high reliability and security during the entire palletising process.

MECHANICAL GRIPPER

End effector gripper.

Our air-operated mechanical gripper is specifically designed to handle open C1 boxes or those similar and can be adjusted to different box sizes manually.

SUCTION PLATES

We have the ability to palletise boxes both individually and in groups thanks to the air-suctioning plates.

OPTIONAL CONTROL OVER CLOSED POSITION

As an option, we offer the servo-driven end effector gripper with control over the closed position and the ability to change box format from the screen depending on selection, with plates for suctioning different box formats.

MECHANICAL GRIPPER

Servo-driven fork gripper

Our mechanical servo-driven fork gripper with suction cups to pick up dividers and bases is perfect for palletising different types of boxes and possible box groupings.

BOX MEASUREMENT VERIFICATION

Installation of a measurement verification of boxes is possible, enhancing the quality of the palletising process.

CONTROL OF THE FLEXIBLE AND DYNAMIC GRIPPER

From the control screen and with personalised settings: delays in pick-up, unloading and even related alarm systems.

200/250 CAP/MIN

200/250 CAP/MIN 200/250 CAP/MIN.

200/250 CAP/MIN. 400/500 CAP/MIN.

400/500 CAP/MIN.